Introduction Of Pneumatic Conveying

Pneumatic conveying system is a application system in which powder or small granular materials are transported from one position to another position in accordance with the technical requirements through air in sealed pipes with pressure and air volume.

Advantages Of Pneumatic Conveying

The pneumatic conveying system has the advantages of low cost, small land occupation, high efficiency, flexible layout, stable operation, great sealing performance, easy operation, avoidance of material pollution help for controlling dust secondary pollution, reducing labor degree and improving automation of conveying process, thus greatly increasing labor productivity rate and minimizing cost and land occupation.

Suitable Materials For Pneumatic Conveying

Materials can be transmitted by pneumatic conveying include cement, fly ash, coal, aluminum oxide, aluminum hydroxide, urea granular, flocculant, activated carbon, grain, flour, limestone flour and other powdery materials.

Comparison Of The Two Conveying Modes

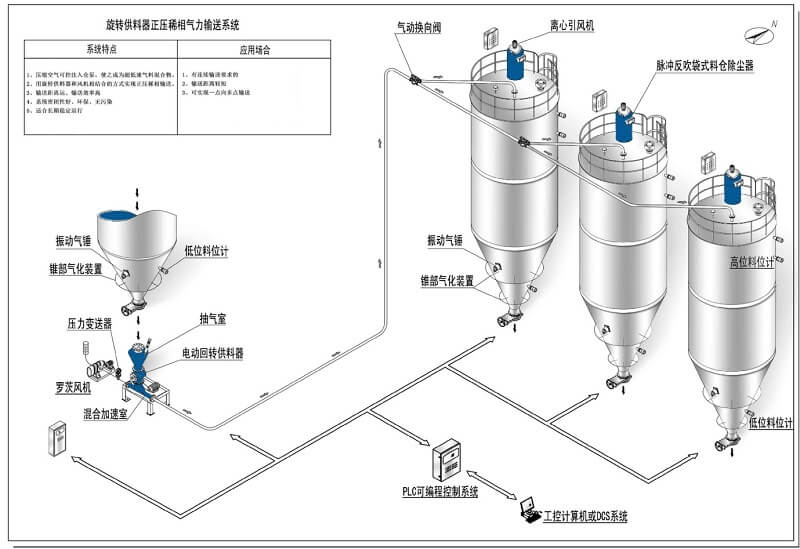

Dilute phase pneumatic conveying is mainly used to transport bulk powdery and granular materials to the specified equipment through air flow that output from roots blower, and then the materials are discharged into pipes for pressure delivery by rotary feeder.

Dilute phase pneumatic conveying is a high speed pneumatic conveying, suitable for dispersion conveying from one place to several places, with materials constantly being suspended in airflow, it is best used for non-abrasive and non-fragile materials with low density, such as flour, corn starch or fly ash.

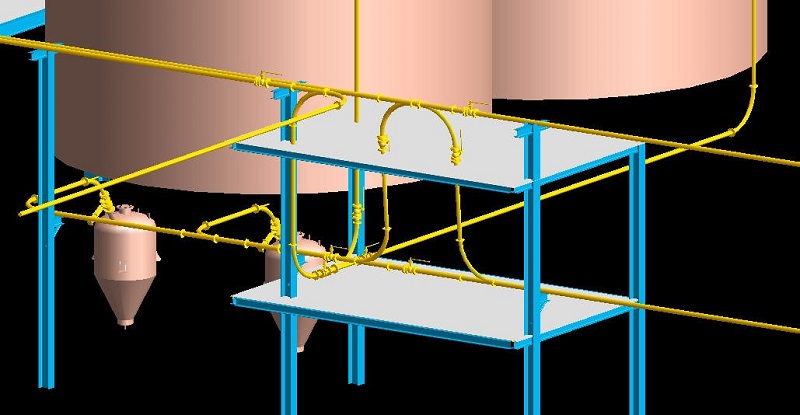

The main equipment of dilute phase pneumatic conveying system: roots blower, rotary feeder, air extraction room, acceleration room, PLC control system, silo roof dust collector, conveying pipeline, wear-resistant elbow etc.

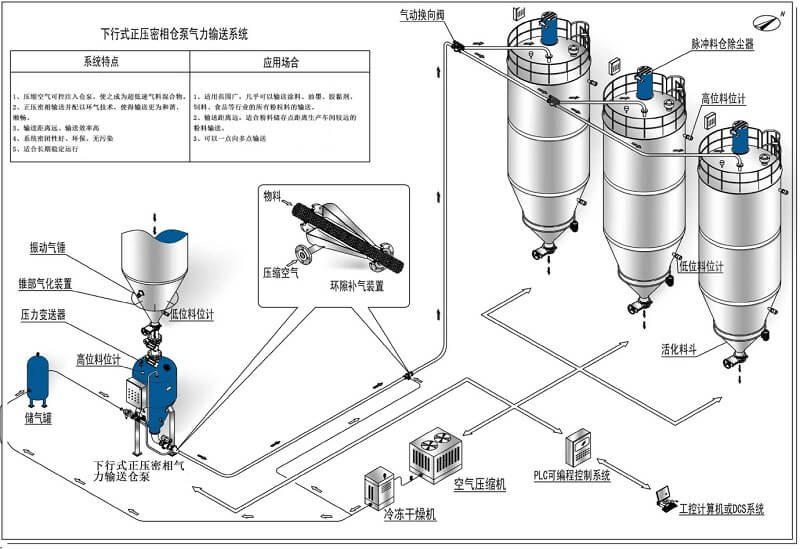

Dense phase pneumatic conveying is often used for conveying materials at low-speed and long-distance with large conveying capacity. During the conveying process, it can realize single-point-to-single or single point to multi-points long-distance conveying, and can finish drying, crushing, screening and mixing technologies. SRON has the case experience in the construction of projects with 1000m conveying distance and 200t/h conveying capacity.

Dense phase pneumatic conveying is a low speed conveying system without materials being suspended in airflow, and there is not much wear on materials and pneumatic conveying system, so it is suitable for conveying fragile materials. And there is no need of air drying equipment for slightly moisture absorbing materials.

Main equipment of dense phase pneumatic conveying: air compressor, gasholder, silo pump, dust collector, PLC control system, pipes and elbows.

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.