Clinker Introduction

Cement clinker is mainly made of limestone and clay. Raw materials are formed in appropriate proportions, burned until part or all of them are melted, cooled and broken into lumps or large granular substances. Clinker is a material used as a cement binder and is a nodular material. Typically, clumps or nodules of clinker range in size from 3 mm to 25 mm in diameter and are dark gray in color. If stored in dry conditions, clinker can be kept for several months without noticeable loss of quality. Because clinker can be easily processed by ordinary beneficiation equipment, there are a large number of clinker transactions in the world. How to store the clinker and ensure its quality has become a concern for clinker producers and buyers.

Precautions When Storing Clinker

1.Protect from moisture. During the transportation and storage of clinker, all kinds of protective work should be paid attention to. For transportation in rainy days, it must be covered with rainproof tarpaulin, and should not be stacked in the open air, so as to prevent the clinker from being hydrated by moisture and reducing its strength.

2.Test first, use later. Although the quality of clinker is stable, in order to prevent damp clinker and clinker from different manufacturers from mixing up, which will affect the quality of cement products, the principle of "inspect first and use later" should be adhered to when entering the clinker plant; In order to prevent the clinker from being stacked for too long, causing the clinker to absorb moisture in the air and resulting in a decrease in strength, the principle of "First come first use" must be adhered to; In order to give full play to the quality advantages of clinker, it is recommended not to mix it with clinker from other manufacturers, especially shaft kiln clinker.

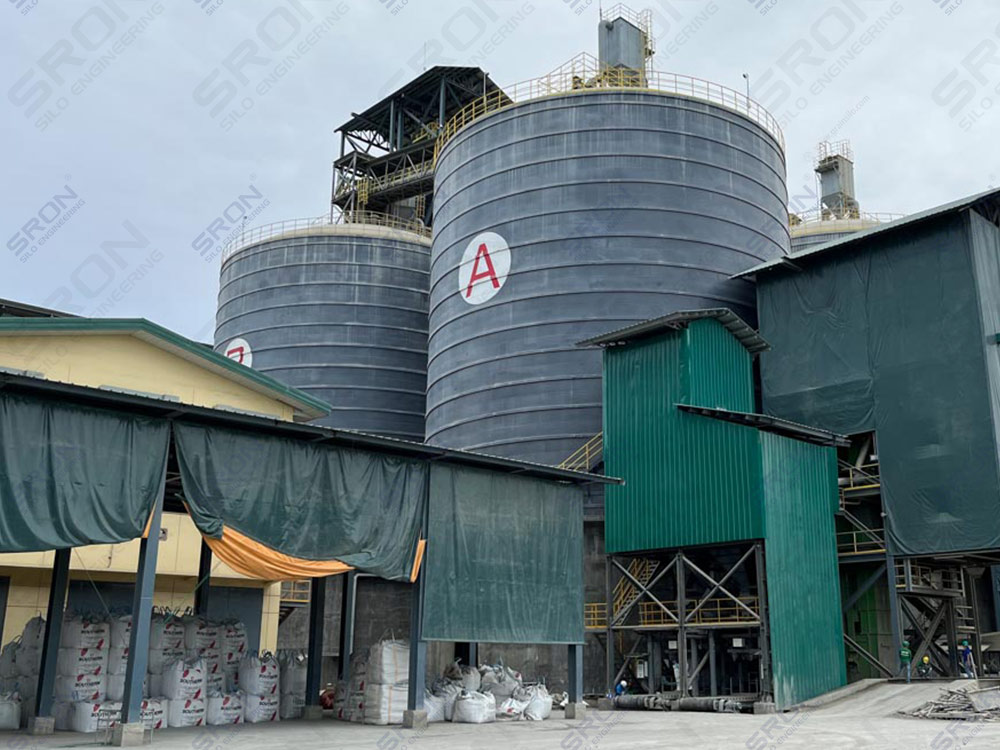

3. In order to ensure the strength and characteristics of cement clinker, clinker should be stored in a moisture-proof and leak-proof steel silo for long-term storage.

Reasons for Choosing Steel Silos to Store Clinker

Traditional storage of clinker in the open air and storage of clinker in bags is dusty and pollutes the environment. And in the case of bad weather, it will reduce the strength of clinker and affect the quality of cement. The use of steel silos to store clinker is not only environmentally friendly and pollution-free, but also further improves the quality of raw materials. SRON provides steel silo storage system solutions for owners, and designs welded steel silos, spiral steel silos and supporting equipment for owners to choose.

Low investment and small land occupation: Due to the adoption of multiple patented technologies, SRON steel silo can save about 50% of building materials and more than 60% of land occupation.

Waterproof and anti-corrosion: SRON's welded steel silo adopts patented vacuum sealing technology, and the clinker quality and physical indicators will basically remain unchanged within 9 months of clinker storage in the silo.

Short construction period and long service life: According to different geological conditions, site environment and capacity, the construction period of steel silo is usually different, the construction period is about 4 months, and its service life can be as long as 30-50 years .

Professional Working Team: From initial project feasibility analysis, project configuration, land planning, financial accounting to project construction and project operation, our engineers will provide you with the most reasonable solution.

Reliable environmental protection system: Air pollution is unavoidable during clinker loading and unloading. We fully consider the requirements of environmental protection when designing the project, and equipped with a dust collector, which can effectively remove the dust generated during the feeding and discharging process, and effectively reduce dust pollution.

.jpg)

Matters Needing Attention When Using Clinker Steel Silo

1. According to the relevant storage regulations, the temperature and humidity of the materials in the steel silo should be checked during use. According to the nature and storage time of the stored materials, take necessary preventive measures (such as cooling) to ensure the safe storage of various materials.

2. When the cement clinker is loaded into the clinker storage silo, the temperature shall not exceed 85°C. If the temperature is too high, it is easy to cause deformation of the storage body, resulting in unsafe factors.

3. Pay attention to the sealing inspection of the conveying equipment, gate valve and other facilities used in the clinker steel silo. The rainproof inspection of the connecting part of the steel silo prevents the rainwater from this link from entering the steel silo and causing the material in the steel silo to deteriorate.

4. The components of large clinker steel silos, such as derricks, ladders, corridors, trestles, etc., need to be inspected every six months and inspection records should be made. Especially painted and welded parts, rusty parts should be treated with anti-corrosion treatment, and remedial measures should be taken immediately in case of welding deformation.

.jpg)

About SRON Silo Engineering

HENAN SRON SILO ENGINEERING Co., Ltd. is China leading reputable EPC Contractor for bulk materials storage silo project, closed storage yard, and bulk material port handling project for grain silo storage solution etc. SRON has the qualifications of Main Contractor for civil construction projects, Main Contractor for mechanical and electrical projects, and Specialized Contractor for steel structure project. We have the complete qualifications in the field of bulk material storage and transportation in China.

SRON focuses on scientific and technological research, achieving new researching technologies each year. Currently we have 62 patented technology, among which 7 are invention patents.

SRON have built projects in more than 30 countries and regions, including Russia, South Africa, Indonesia, Malaysia, Kenya, Mongolia, Philippines, Peru and so on, with more than 900 sets of steel silos and up to 3 million tons of materials storage capacities, SRON quality and reputation are highly recognized by global users. For more information about Sron Silo Engineering and the Storage silo solution, please contact us or leave your requirements.

Technology Builds the Beauty of Project

.jpg)

.jpg)