Introduction

SRON Steel Silo System in Cement Plant Industry

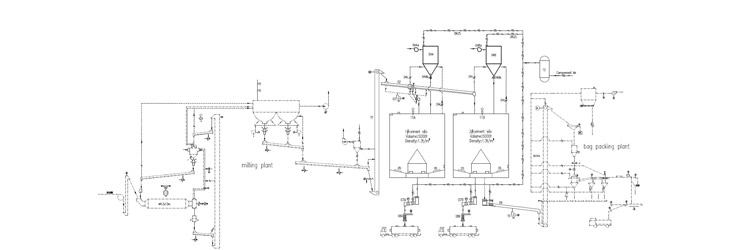

Steel Silos System used in cement plant industry for storage of various types of raw or finished materials, It is a important participant equipment of cement plant. The silo size/height design is adjustable to match with flow requirement of whole cement plant, well arrangement of silo unloading fluidization system is a must and the whole system design and equipment must bear high working load requirement at cement plant.

Process

Usually the whole system includes: cement feeding bucket elevator, dust collector system, silo aeration system, cement unloading system, bulk truck loading, bag packing system, bag palletiser and bag truck loading system.

Economical Silo Model for Choice

| Single Silo Volume | Silo Model Choice | Advantages |

| 100-800m3 | Bolted Silo | Easy Installation, Cost Saving |

| 500-7000m3 (Not for Hot Clinker) |

Spiral Folded Silo | Germany silo technology Good anti-corrosion performance as the materials for silo is by hot galvanized steel plate High Sealing Performance Strong silo solidity Short Construction Time Cost Saving |

| 7000-20000m3 (Not for Hot Clinker) |

Welded Silo | Applicable for various types of materials Big volume of single silo High performance of sealing |

Exhibiton Information

Contact SRON you will get customized project solutions.

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.