Our company has obtained more than 60+ patents in silo shape and internal structure, and has scientific and advanced silo design concept.

Advantage of Welded Steel Silo Type

1.Large storage capacity: the diameter of the silo is 80m, and the capacity of a single silo is 5,000-100,000 tons, which can be increased if there are special needs;

2.Low initial investment: due to the adoption of a number of patented technologies, it can save about 50% of building materials and more than 60% of land to be acquired;

3.It has good air tightness and adopts patent technology of vacuum sealing: The physical indexes of cement quality are basically unchanged within 9 months of storage inside the silo;

4.Energy saving and environmental protection: patented dust removal technology is used in the process of warehousing and outbound, which will not cause pollution to the surrounding environment;

5.High strength, long service life: with to the standard maintenance, service life up to 30-50 years.

As a high-load thin-walled structure building, the safety of the steel silo has a high priority. SRON Engineer fully consider various factors, like dead loads, dynamic loads, grain loads, earthquakes, wind loads, snow loads, temperature effects, etc. in the early design stage of silo system.

For overseas projects, we fully consider the differences of national standards, uses international standards and professional industry software such as STAD PRO and SAAP2000, and uses finite element analysis to produce effective structural calculations.

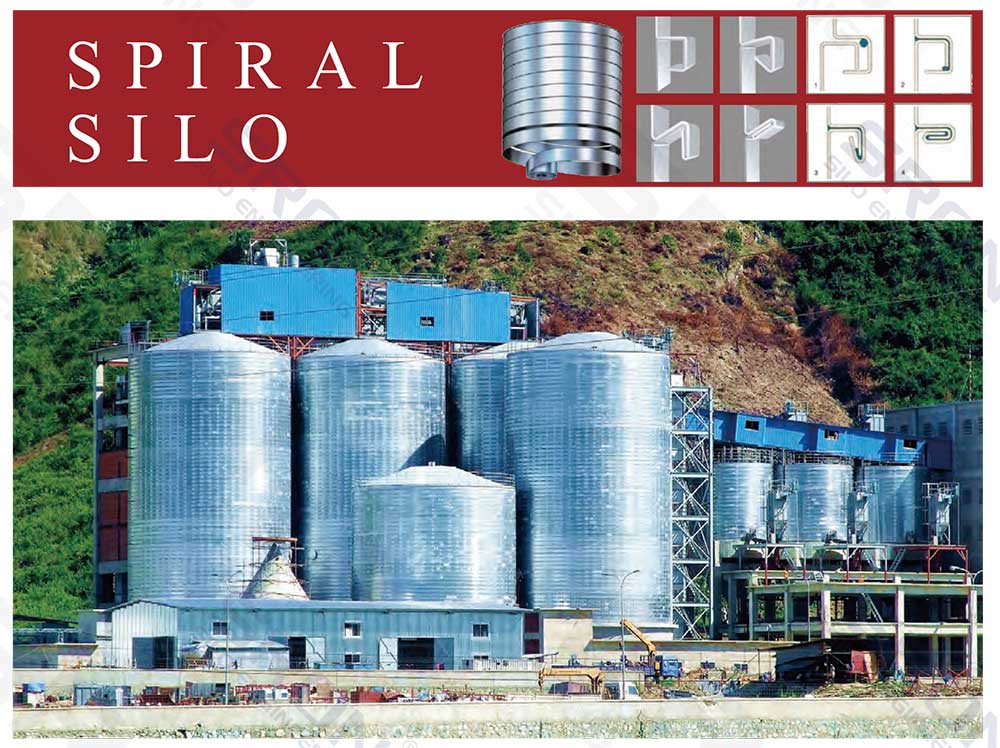

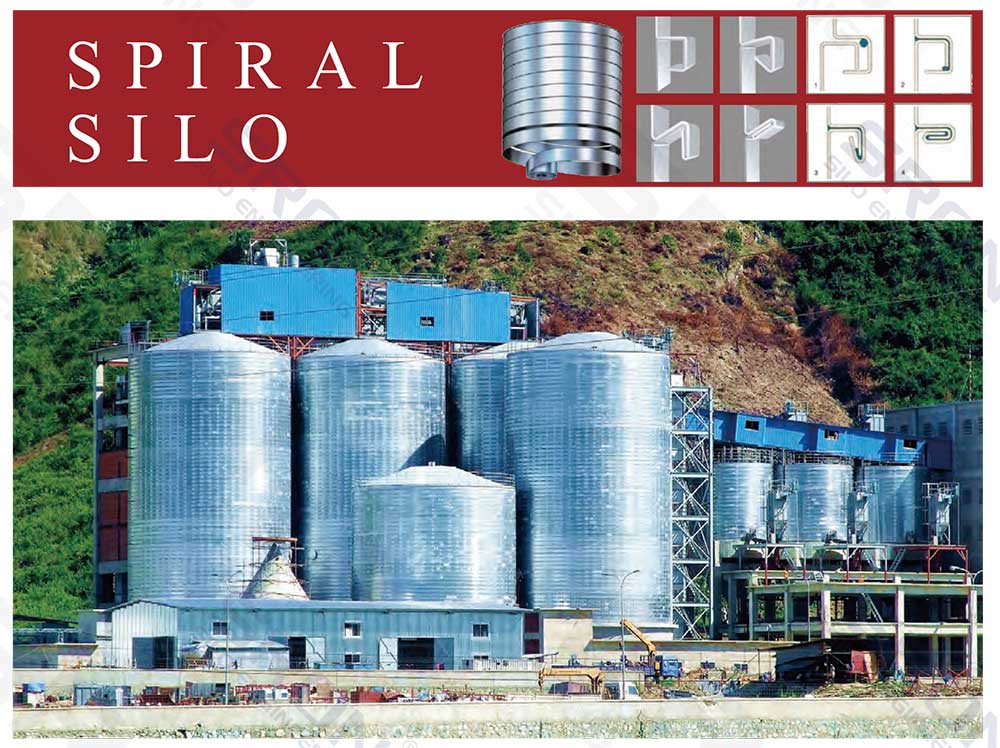

Spiral Sealing Steel Silo

Spiral silo refers to the silo which is made by spiraling the steel plate with a certain width into the rolling equipment during construction.

Spiral Sealing Steel SiloThe protruding undercut thickness of the spiral silo is 5 times of the original steel plate thickness, which strengthens the structure and the bearing capacity of the silo. The structure of the silo body is integrated without any holes, bolts and screws, so it has good air tightness.

In addition, the use of galvanized steel make the silo reach a good corrosion resistance & long service life. Due to the use of special equipment for spiral silo, the quality of any part of the silo can be ensured.

Due to the limitation of the thickness of the silo plate, the storage capacity of a single silo is generally not more than 8,000t, especially in the areas with high wind load and seismic fortification intensity, the type selection should be strictly in accordance with the calculation results to ensure safety and firmness.

Advantage of Spiral Sealing Steel Silo

High strength: the inner wall of the silo has vertical reinforcing ribs and transverse spiral undercut ribs, which greatly enhances the strength of the silo and has strong wind, earthquake and snow load resistance;

Good sealing performance: the cylinder of the silo is connected by spiral undercut, with excellent sealing performance;

Short construction period: silo could be put into use as soon as possible to create benefits for users;

Long service life: the cylinder of the silo is made of hot-dip galvanized coil, and the top of the silo is treated by galvanizing process, with strong corrosion resistance and long service life;

Space saving: the distance between the two silos can be as low as 500mm, which can make full use of the space and reduce the floor area.

Light weight: the silo has low weight, which greatly reduces the load and cost of the foundation structure.

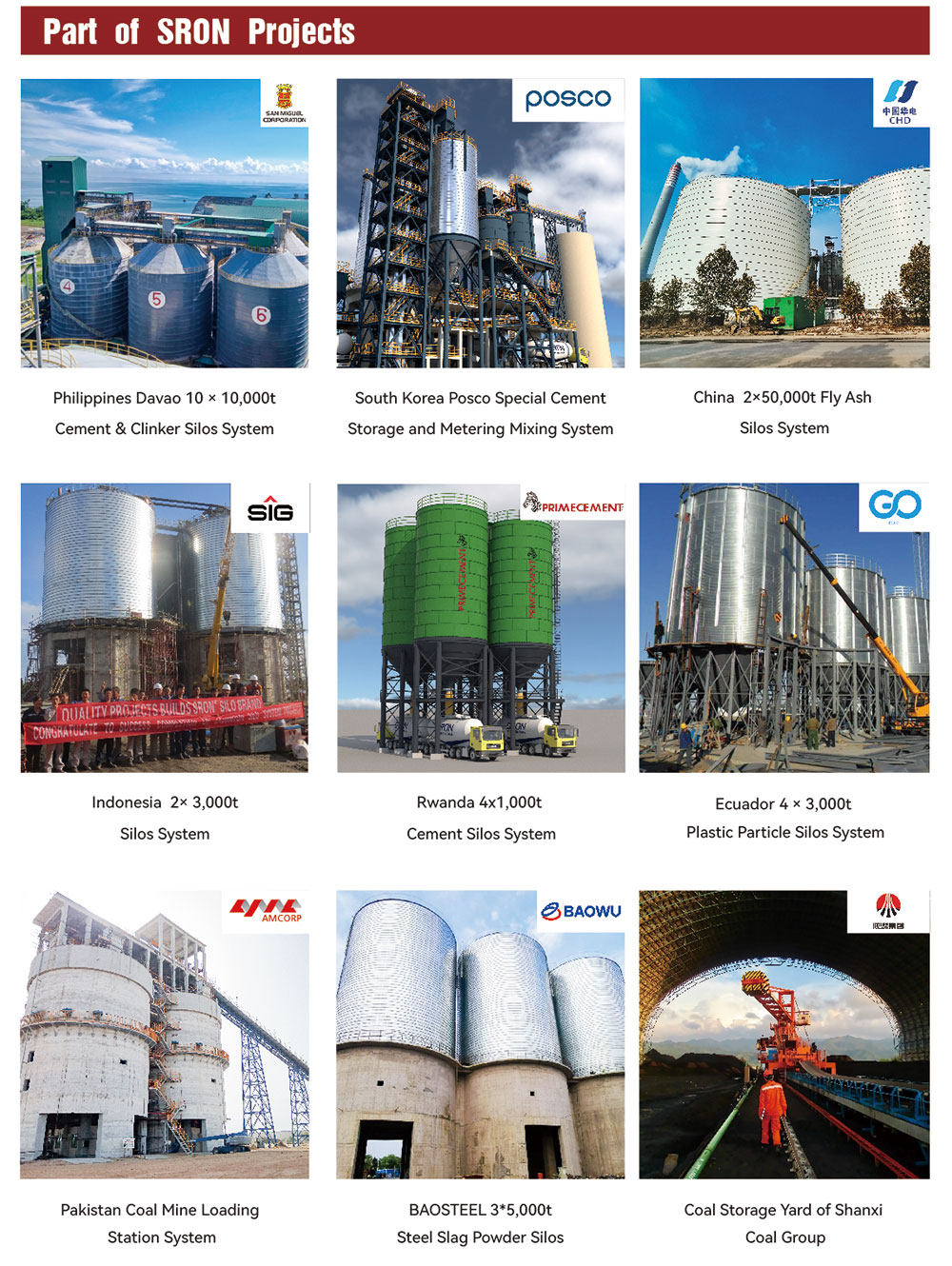

3.SRON Silo System Solution Project Cases

Sron Silo Engineering has made many EPC Silo System Project all over the world

.jpg)