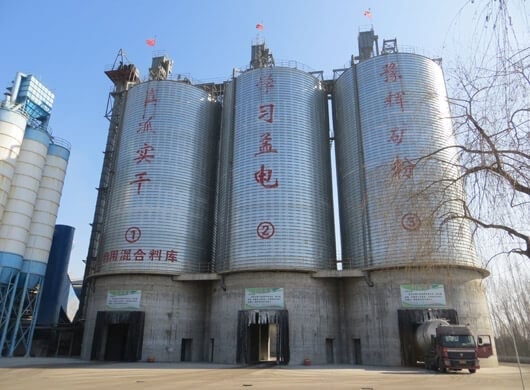

Hydrated lime density is 700kg/m3 with comparatively strong moisture absorption. The silo top feeding angle and unloading angle is also special, and must with scientific arrangement of aeration system ensuring smooth and high rate unloading.

Silo must with strict treatment for moisture proofing at construction and before application.

Introduction

Hydrated Lime Silo Systems provide a more cost-effective solution as the equipment is simpler and does not need to be designed to contain the exothermic reaction that takes place when slaking pebble lime. Another benefit of a hydrated lime system not creating an exothermic reaction is that it is able to create a higher concentration slurry, which helps to reduce operational costs.

Hydrated lime silo system is used in various industries, our expertise experienced team will furnish you professional practical solution while considering your special requirement of investment, available land, local geographic and climate situations.

And Hydrated Lime Silo System generally includes: pneumatic lime feeding system, silo aeration system, lime discharging system, bulk truck loader system, bag packing system, packed bag palletizer or truck loading system, dust collector system, PLC control system, and related steel structures and platforms with details as following shown.

Lime materials is with some sticky features. The discharging cone angle is normally at least 65 degree and to avoid blockage or non-smooth discharging. Air canoon is required to faciliate discharging.

Details

Silo Feeding System

Silo Feeding System Pneumatic Feeding

Pneumatic Feeding Silo Aeration System

Silo Aeration System Silo Discharging System

Silo Discharging System Bulk Truck Loading System

Bulk Truck Loading System Dust Collector System

Dust Collector System Bag Packing System

Bag Packing System AIR CANNON FOR LIME SILO

AIR CANNON FOR LIME SILO AIR CANNON FOR LIME SILO

AIR CANNON FOR LIME SILOExhibiton Information

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.