PATENTED SILO AERATION TECHNOLOGY

SRON has several patents for our flat bottom silo aeration system

For a flat bottom silo, a tight, scientific designed aeration system is essential for power materials storage like for cement, fly ash and lime. This system must ensure the full automatic controlled aeration, automation of roots blower system, smooth unloading, high cement empty rate and rare failure.

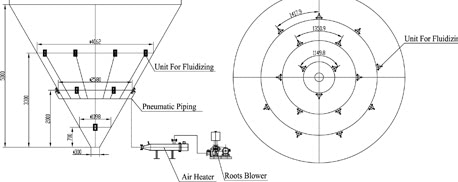

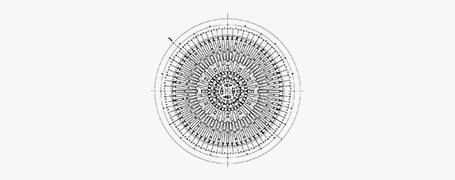

Cement silo has a tapered cone in the silo center to relief pressure. The silo bottom circle discharging zone has a 10-12 degree angle with horizontal floor and is divided into several discharging zones. When the air enter into the discharging zones, the cement, fly ash or other powder materials will flow into the pressure relief cone and unloaded, the inside silo cement, fly ash or Other powder materials will swirling collapse down by material gravity and thus creating the effect of homogenization also.

The main equipment for the system is by open aeration chute, roots blower and its pneumatic piping system, needed gauges and meters, PLC control system. The system design must be adjusted or enhanced based on local temperature and moisture situations.

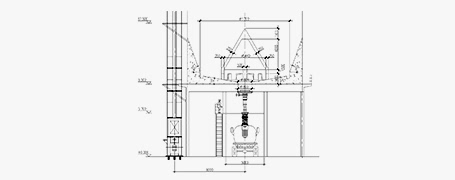

For cone structure silos, the aeration is different but also important

Cone structure silos has the advantage of gravity unloading, But the fluidizing discharging aeration box is a must for guarantee of absolute non-caking during unloading process.

As one just use the fluidization system at urgent case of non-smooth unloading or caking situation, so it is very energy saving solution. While the equipment cost is also not expensive.