The HMC integration type dust collector is a small size integrated bag filter that developed from similar products. It is composed of four parts: shell, filter bag assembly, Filter bag purging device, and ash discharge device.

The air inlet of HMC type dust collector is set on the ash hopper. When the dust gas enters the ash hopper from the air inlet, it first touches the baffle at the end of the air inlet pipe. Due to the inertia effect, the coarse dust in the gas directly enters the ash hopper, playing the role of pre dust collection. The air flow into the ash hopper then bends upward through the filter bag with metal framework inside. The dust is collected on the outer surface of the filter bag, and the purified gas enters the ash cleaning solid on the upper part of the filter bag chamber and is collected into the air outlet pipe for discharge. The indoor dust collection bag is divided into several rows, and each row of dust collection bag is cleaned according to the given time interval. When the pulse valve is opened, high pressure air is sprayed into the filter bag to remove the dust on the surface of the filter bag.

Adopting pulse jet ash cleaning method, it has the advantages of good ash cleaning effect, high purification efficiency, large air volume, long filter bag life, small maintenance workload, safe and reliable operation, etc.

It is widely used in the dust removal and material recollection of non-fibrous industrial dust in various industrial and mining enterprises such as metallurgy, building materials, machinery, chemicals, mining, etc.

The air box pulse bag dust collector consists of a shell, an ash hopper, an ash discharging device, a support and a filter bag purging system. It is characterized by the use of compartments for dust cleaning in turn. When a certain chamber is used for dust cleaning---purging, the filter air is cut off----the air flow will be cut-off.so as to avoid the dust secondary ash laying. Therefore, the dust collector can capture the gas with dust concentration up to 1000g / m3 (standard).

This series of dust collectors are outdoor-style and consist of different numbers of rooms and different bags in each room, which are composed of many different specifications. The normal quantity of bags in each compartment are: 32, 64, 96 or 128 pieces. The whole series has 33 specifications, the diameter of the filter bag is Φ133mm, and the length of the filter bag is 2450mm and 3060mm. This series of dust collectors can be operated under negative pressure or positive pressure without any change in the body structure. Its dust collection efficiency can reach more than 99.9%, and the water content and dust concentration of the purified gas is less than 30mg/m3 (standard). The heating device is necessary if the dust collectors are used where outdoor calculated temperature is ≤0℃ in cold areas, and the housing of the dust collector should also be equipped with an insulation layer.

The air box dust collector integrates the advantages of various bag dust collectors, such as chamber back blowing and and pulse filter bag purging, and overcomes insufficient back-blowing, solves simultaneous problem between pulse cleaning and filtration, thus expanding the application of the dust collector. This kind of dust collector structure improves dust collection efficiency and prolongs the service life of the filter bag. At the same time, it has the advantages of simple structure, easy operation, good dust removal effect, and low operating cost.

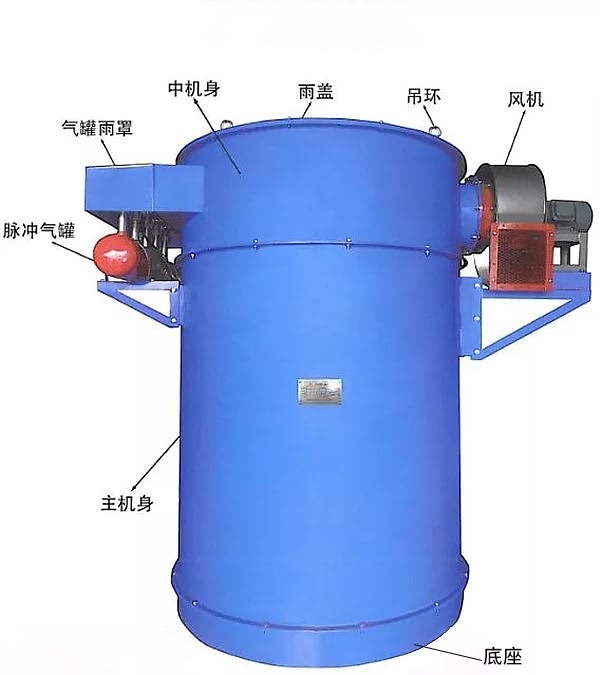

The small pulse bag filter is mainly composed of the steel base, the ash hopper, the middle box, the upper box, the air inlet and outlet, the filter bag, tthe filter bag purging device, and differential pressure feedback type pulse controller.

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

BE STRICT ON EACH PART OF EQUIPMENT, DETAILS MAKES PERFECT