PATENTED TECHNOLOGY OF SPIRAL FOLEDE SILO

SRON Start Construction of Spiral Silos Since 1990s

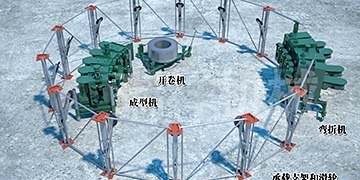

Manufacture Process of the Spiral Folded Silo

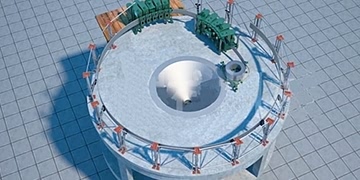

Position the Silo Profiling Unit

Steel Plate-Curve-Form Silo

Cut Level Line for Install Silo Top

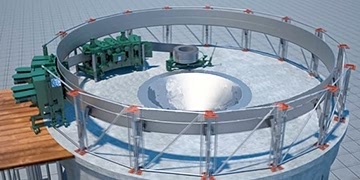

Finish Whole Silo Top Structure and Continue Silo Profiling

Stop and Weld Inner Rib When Silo Arrive at Certain Height

Finish Silo Project

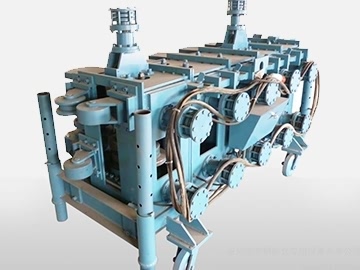

Our Silo Manufacture Unit

We have 20 sets SM30, SM40, SM50 silo profiling unit, part of them are imported from Germany. We will use the different model of silo profilling units according to the different silo diameter and plate thickness. The whole unit is composed by de-coiling machine to send the steel plate to profile machine, profile machine to curve the steel plate for certain diameter, folding machine to bend and seam the 5-layer joint structure, supports structure that rise the silo body by steady wheels.

Galvanized Steel Plates

Decoiling Machine

Profiling Machine

Folding Machine

Supports

Working Process