Storage Material: Cement, Clinker, Fly Ash, Slag Powder, etc.

Storage Capacity:200 - 100000 Tons

Silo Diameter: ≤80m

Application: Cement Plant, Cement Transit Center, Concrete Batching Plant, etc.

Silo Type: Welded Steel Silo, Bolted Steel Silo, Spiral Sealing Steel Silo

Introduction

Cement Steel Silo Introduction

SRON cement silo, also named cement storage silo, cement steel silo, have three common silo types : welded silo, bolted silo and spiral silo for clients’ choosing. Cement silo system includes cement storage silo and other auxiliary equipment, constructed for cement storage and transportation, widely used in cement production plants, concrete batching plant, cement transit center.

For the cement storage silo have a special requirement of high strictness on sealing, so usually the silo system solution for the cement plant used welded silo or spiral silo

As a professional cement silo manufacturer, SRON can help clients select the most suitable and economical steel storage silo according to their requirements. Our salesmen and engineers can provide in-time reply, professional silo knowledge and customized service to clients for their needs of cement silo construction, silo design, silo capacity and silo type, etc.

Storage Capacity:200 - 100000 Tons

Silo Diameter: ≤80m

Application: Cement Plant, Cement Transit Center, Concrete Batching Plant, etc.

Silo Type: Welded Steel Silo, Bolted Steel Silo, Spiral Sealing Steel Silo

Cement Silo System: Silo Feeding System, Pneumatic Feeding, Silo Aeration System, Silo Discharging System, Silo Aeration System, Bulk Truck Loading System, Dust Collector System, Bag Packing System

As a silo project company with over decade years experiences, SRON provides customized and EPC services according to different functional needs, site and climate conditions and investment plans of each client's project.

If you are interested in our cement silo system or would like to know specific quote or details, please click here.

Details

Low Initial Investment: Due to the adoption of various patented technologies, it can save about 50%of building material and more than 60% of land to be acquired.

Good Air Tightness: Adopts patent technology of vacuum sealing, the physical indexes of cement quality are basically unchanged within 9 months of storage inside silo.

Energy Saving and Environmental Protection: Patented dust removal technology is used in the process of silo feeding and discharging, which will not cause pollution to the surrounding environment.

Long Service Life: With the standard maintenance,service life can be up to 30-50 years.

Short Construction Period: Help the clients to put into use and recoup funds quickly.

Light Weight: The silo has low weight,which greatly reduces the load and cost of the foundation structure.

Cement Silo System Introduction

SRON cement silo system generally includes: cement feeding system, silo aeration system, cement discharging system, bulk truck loader system, bag packing system, packed bag palletiser or truck loading system, dust collector system, PLC control system, and related steel structures and platforms. usually our technical can design the whole cement silo system according to customer's requirement.

Cement Silo Safety Analysis

3D Display for the cement silo system

Each of SRON silo project is a turn-key solution. Our experienced engineers will be beside with you to design and construct the most suitable, dependable and economical project through the whole process of project feasibility study, analysis, construction, maintenance and operation.

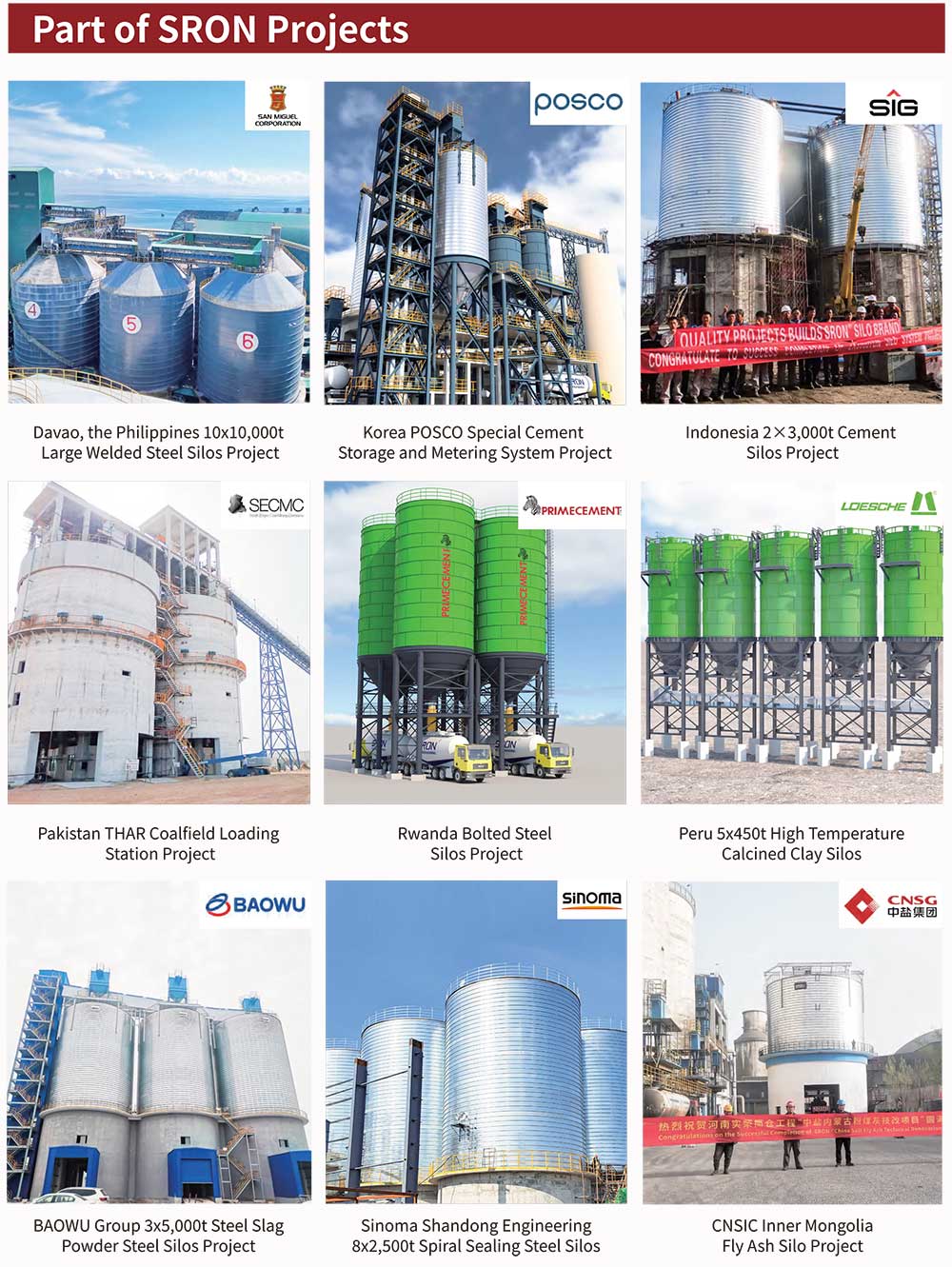

Global Cases of SRON Cement Silo

We have built storage silo projects in more than 30+ countries and regions, including Russia, United States, Indonesia, Malaysia, Kenya, Mongolia, Philippines and Peru with more than 900 sets of steel silos and up to 3 million tons of materials storage capacities, SRON quality and reputation are highly recognized by global users.

Exhibiton Information

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.