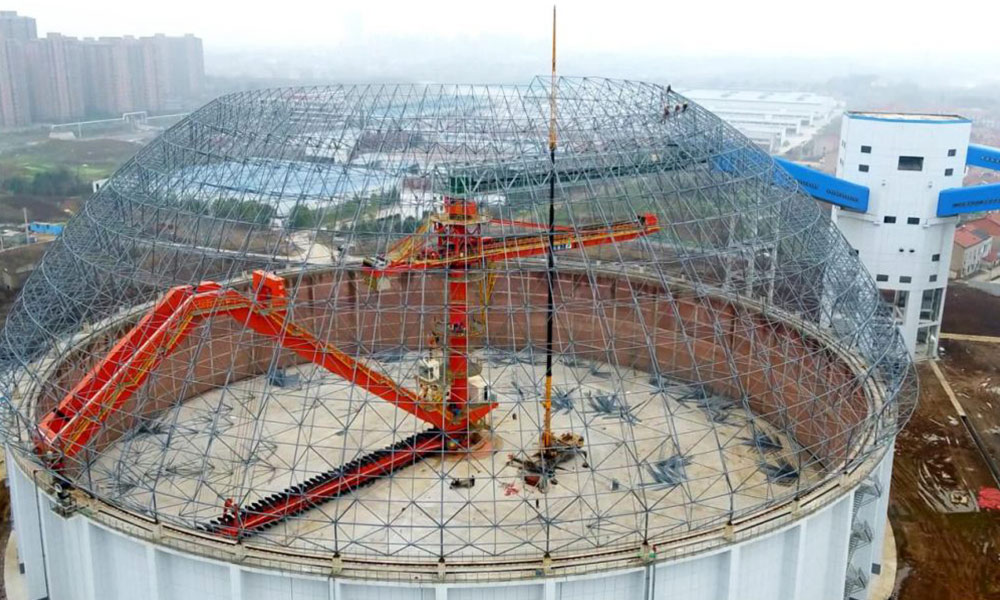

With the increasing requirements for environmental protection, the control of dust pollution in coal storage yards of thermal power plants has been put on the agenda. Circular coal storage yards are increasingly used by power plants due to their advantages such as large reserves, high environmental protection, fully automatic operation, and reduced coal loss during storage. The diameter of circular coal storage yard can be comprehensively determined based on technical and economic analysis based on site conditions, geological construction conditions, storage capacity requirements and project investment.

Environmental Protection of Circular Coal Storage Yard

As the environmental protection requirements for industry are getting higher and higher, circular stockyards have significant advantages in this regard. The reason is that it is a sealed system itself, and it takes many measures to control dust:

(1)The stacking arm adopts a pitching mechanism, and the stacking arm tilts down when starting to stack, thus reducing the height at which the coal falls;

(2)Use spray dust suppression when stacking coal;

(3)When stacking coal, the stacking arm drops coal along the original coal pile, so the height of coal dropping is very small and the dust is very small;

(4)Although natural ventilation is adopted, the height of the ventilation holes on the grid has been scientifically calculated so that the gravity of the coal dust at this point is greater than the buoyancy, and dust overflow will not occur.

Economic Efficiency of Circular Coal Storage Yard

1.The circular coal storage yard occupies a small area and has high site utilization rate.

2.Easy, fast and safe installation.

3.Advanced and reliable equipment with high degree of automation.

4.Low investment cost, stacking and reclaiming operations can be carried out continuously and simultaneously.