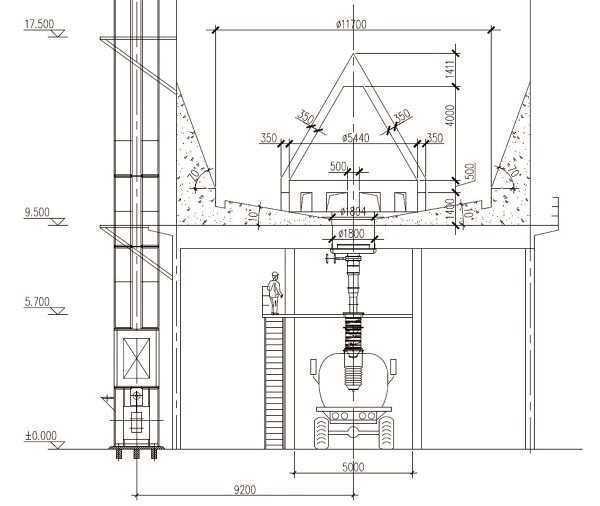

In order to ensure smooth discharging and material homogenization, a gasification device is arranged at the bottom of the steel silo. The steel silo adopts roots blower for air supply. The inside bottom of the silo is conical and inclined to the central chamber. The bottom of the silo is divided into 6 ~ 14 aeration areas, which are covered with aeration boxes. During discharging, the aeration boxes are opened symmetrically in turn to make the materials fluidized and flow to the discharging cone. Then the material in the cone is aerated and stirred to become active, which has good fluidity, and can be smoothly transported into the distributing box of the unloading device.

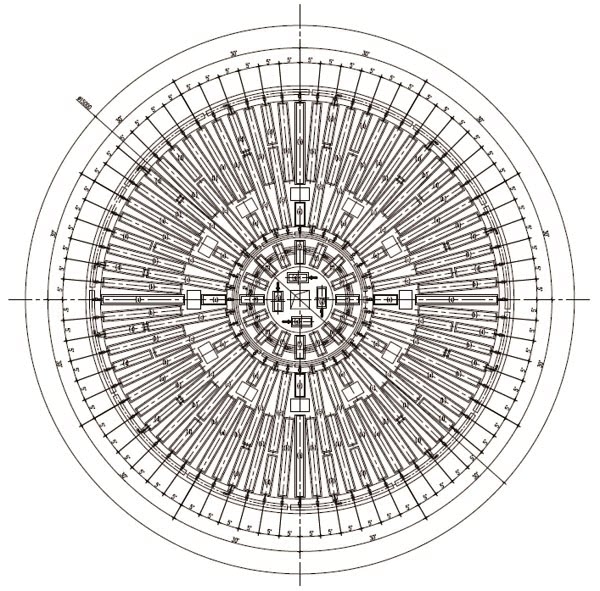

There are multiple discharge channel with discharge holes and conveying equipment at the bottom of the steel silo. The silo bottom backfill type and whether to choose a auxiliary air sources is depending on the stored material's different features. Each discharge hole is an independent discharge unit. By controlling the valve which connected with the conveying equipment, each discharge hole can be controlled manually, or realize the whole system fully automated.

The materials in the flat-bottom steel silo naturally accumulate at a repose angle. There are multiple discharge routes with discharge holes and conveying equipment at the bottom of the steel silo. Each discharge hole is an independent discharge unit. By controlling the valve which connected with the conveying equipment, each discharge hole can be controlled manually, or realize the whole system fully automated.

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

BE STRICT ON EACH PART OF EQUIPMENT, DETAILS MAKES PERFECT