A Hazardous Waste Treatment Project in China

- Project Overview

-

Storage Material:Dried sludge, slag, auxiliary materials

Silo Type: Welded Steel Silo

SiloProject Include:10 welded silos, bucket elevators,scrapers, metering devices...

Introduction

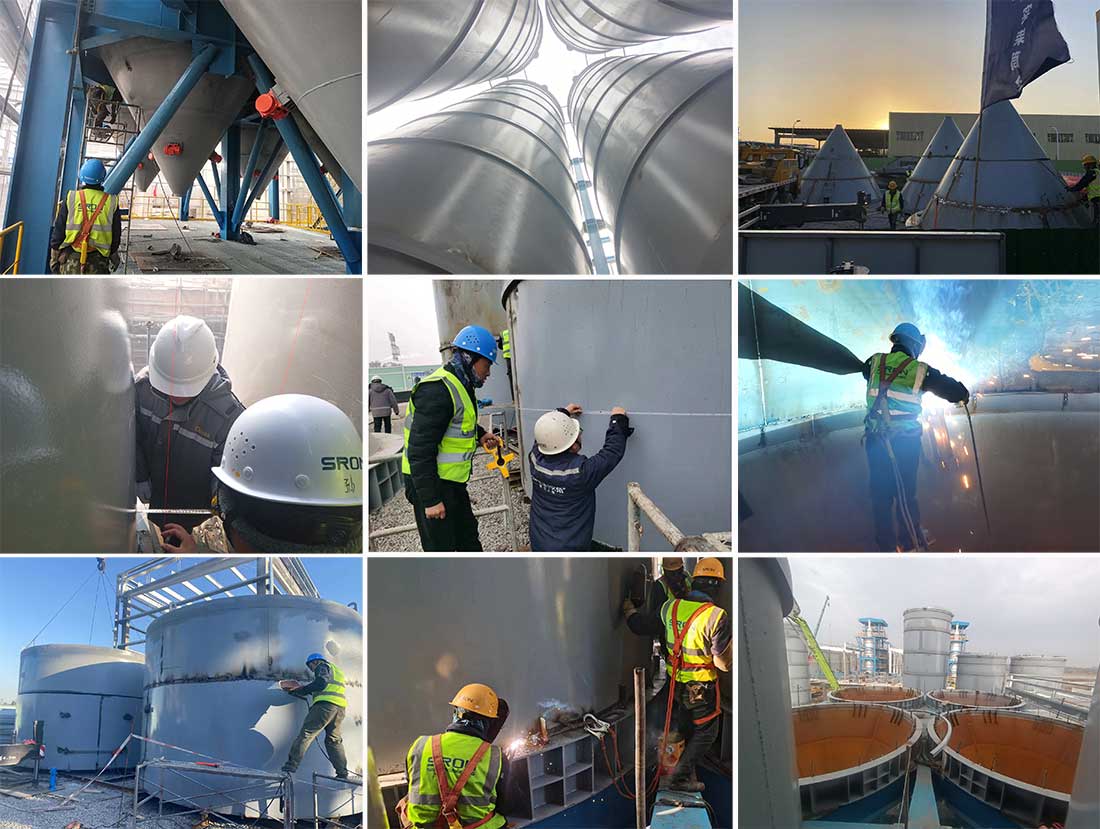

This project is a domestic hazardous waste treatment project undertaken by SRON company, which covers 10 welded silos, including bucket elevators, scrapers, metering devices, electrical automation and other ancillary facilities for storing dried sludge and slag, as well as auxiliary materials.The overall project has many equipment, many measurements and complicated process. SRON has technical engineers in various professional fields, such as process, electric, equipment, steel structure, etc., with rich experience in project design and construction. During the project design process, the technical engineers, after communication and exchange with the owner, and combined with the current situation of the project, formulated a design scheme that meets the owner's needs, which was highly recognized by the owner.

Faced with the above various challenges and strict requirements, SRON formulated a scientific and reasonable design and construction plan, through the use of various types of feeding methods such as bucket elevators, scraper conveyors, pneumatic conveying, automatic bag opening and so on. Differentiated arch breaking measures solve the problem of discharging materials with many varieties and widely different properties, avoid material hardening, and ensure smooth fluid discharge of materials. At the same time, in order to meet the requirements of continuous measurement and batching technology, SRON adopts a reduction scale to stabilize the feeding and measurement of materials, which ensures the stability of feeding is better than 0.5% and the accuracy is better than ±0.5%, which guarantees the stability of feeding.

Details

.jpg)

.jpg)

.jpg)

Project Completion

Exhibiton Information

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.